2020 Wave1 New Features Of SCM – IoT, Planning, Portals And Warehouse Management.

Wave 1 brings in a number of new features in SCM, here are the details on IoT intelligence, planning, portals and warehouse management of SCM.

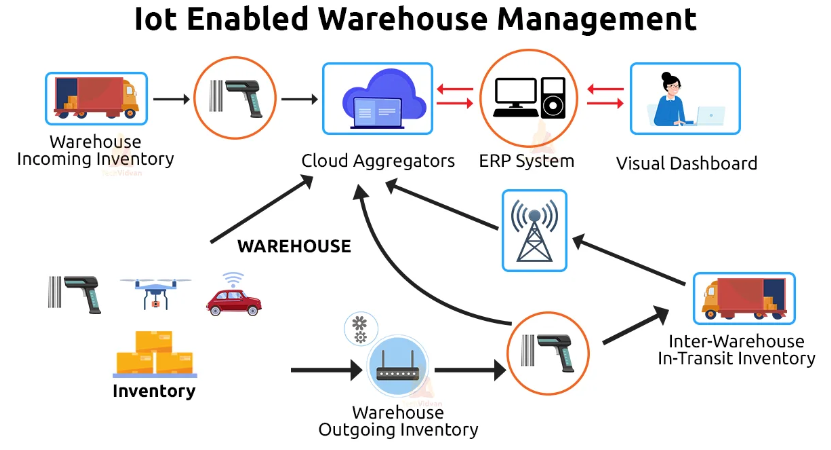

IoT intelligence

1) IoT intelligence core insights

Delayed orders: 2020 wave 1 brings in new features to tackle delayed orders, it enables notification services and actions for delayed production orders and for its impacted operations. Enables users to take relevant business actions for delayed orders, including the ability to view impact or create a maintenance request.

Equipment down: Provides notification services and actions for managing equipment-down scenarios. Users are equipped with features that helps to define metrics for machine-down thresholds and notifies users during such scenarios. Enables users to take relevant business actions for delayed orders, including the ability to view impact or create a maintenance work order.

Quality anomaly: Provides notification services and actions for managing quality anomalies. Users are equipped with features that helps to define quality attributes for products and get notified when exceptions to these attributes occur.

Automated inventory updates: Provides automated inventory updates and the ability to define batching rules.

No-code capability: code-free method for users to connect their machines to IoT intelligence service.

Planning

2) Master planning includes items with on-hand inventory when pre-processing filters are enabled

Once the new feature, Include items with on-hand when pre-processing filters is enabled in Feature management, it ensures that items with on-hand inventory will always be included in the master planning run when the Pre-processing: Automatically filter by items with direct demand setting is enabled on the Master planning parameters page.

Portals

3) Customer self-service experiences

To give the customers a sense of self service experience, the customer portal template is introduced into D365 SCM environment. It is a Power Apps portals template available in the Power Apps template gallery allowing companies to create an externally facing website linked to the SCM.

Though it doesn’t provide end-to-end solution, it helps companies bring dual-write, Power Apps portals, and Supply Chain Management together to create a self-service experience for the customers.

The feature provides following functionality:

• View order history

• View account information

• Create orders

• Preconfigured web roles and entity permissions for Power Apps portals users.

Warehouse management and transportation

4) Catch weight product processing

This feature provides a catch weight tag that captures the weight of the particular unit. This feature cancels out the reductant process of weighing the product multiple times, and instead weigh the product only once—at the time of receipt. This feature is beneficial for products that don’t change weight over time (such as frozen shrimp) and products that have a handling unit of measure that is shippable (such as a box of shrimp). The user scans the catch weight tag to identify the weight at the time of picking or packing based on the product configuration, also, the invoicing will be done based on the captured catch weight tag.

5) Inbound and outbound logistics improvements

These previously existing features are now available for the customers to include these features in production environment through Feature management

Inbound:

• Quality check – Allows to do quality checks right at the time of receiving to the inbound dock area.

• Put away clusters – This features allows to segregate multiple license plates at once and put away to different locations.

Warehouse operations:

• Packaging product dimensions – This allows users to have different sets of dimensions for items with nested packing

• Local utilization – This serves as a tool for warehouse managers to easily view and filter the volumetric utilization of location across the warehouse.

• Location license plate positioning – In a multi-pallet location, this allows the user to see where the LP is located. It adds a sequence number to the plate for each licensing put to a location.

• Location product dimension mixing – This new location profile functionality allows you to decide whether configurations, colors, style, and sizes can be mixed on a certain location (profile) or if only one or a combination of some of those dimensions can be put to the same location.

• Flexible warehouse-level dimension reservation – This enhancement introduces flexibility in the inventory reservation policy to allow businesses who sell batch-tracked products and run their logistics as WMS-enabled operations.

Outbound:

• Small package shipping – helps for setting up carrier login credentials, printing labels received back from carrier web services, charging freight to customer third-party accounts, additional freight terms, and additional accessorial delivery types.

• System-directed work sequencing – this setup offers the ability to sort and filter which work orders the system will present to the user for execution.

• Wave load building – Advanced load building allows the wave to assign the shipment to an existing load.

• Warehouse slotting – Warehouse slotting allows you to create replenishment work at any time based on order demand.

• Wave label printing enhancements:

Allows labels to be printed according to number of cartons on a single work line, without using the containerization feature. Includes enumeration of the labels, support for reprint of labels, voiding of labels, clean-up of wave label history.

6) Mass deployment for Warehouse mobile app

The feature allows users to silently perform a mass deployment of the connection settings for the Warehouse mobile app. Customers can choose the deployment tool of their choice (such as Microsoft Intune) to deploy and service warehouse mobile devices.

7) Enhancement to use existing catch weight tags with warehouse management

This feature adds support for using a mobile device to report a production order as finished when catch weight tags have been registered in advance for the appropriate order.

Use the Mobile device menu items page to add this feature to any mobile-device menu item that uses the Report as finished and put away work creation process.

8) Warehouse management – inbound load management enhancement

The feature gives a new association of the purchase order inventory transactions with the load ID when receiving from the Warehouse Mobile device. Also has an update to the inbound load warehouse handling operations called as “Multiple product receipt postings per load.” this allows multiple product receipt postings for the same load. Wearhouse managers can now keep the load open even after running the product receipts, this allows multiple quantity register for the same load. These enhancements will allow ISVs to build more robust solutions when integrating with the load entity.

Trade and source

9) Enterprise scale – purchase system performance

Based on the customer feedback on purchase order processing scenarios, some key improvements have been made to system performance which helps customers who are dealing with a large volume of purchase orders in different scenarios.

10) Enterprise scale – sales system performance

Same way there are a few key improvements done to the system performance which can assist customers dealing with a large volume of sales orders. These improvements help in both manual entry order and import scenarios.

Find more about the new features of Trade and Sources on our next blog.

For more details kindly visit our LinkedIn page:

https://www.linkedin.com/company/allgrow-technologies-pvt-ltd/mycompany/

or you can write us on contact@allgrowtech.com

DO YOU WANT TO TURN YOUR IDEA INTO REALITY

Services we offer

Software and Web Development

Consulting Services

Development

Frontend

Backend

DevOps

SAAS

Locate us at

Karnataka

My Office Space, No 22/B, 2nd Floor,

BM Habitat Mall, Gokulam Main Road,

Jalakashmipuram, Mysore-570012,

Karnataka, India.

Uttar Pradesh

4th Floor, Bhavya Corporate Tower,

Vibhuti Khand, Gomti Nagar, Lucknow,

Uttar Pradesh 226010

Get in Touch

For Business – contact@allgrowtech.com

For Career – hr@allgrowtech.com

© 2026 ALLGROW TECHNOLOGIES. ALL RIGHTS RESERVED.